Phoenix Raceway

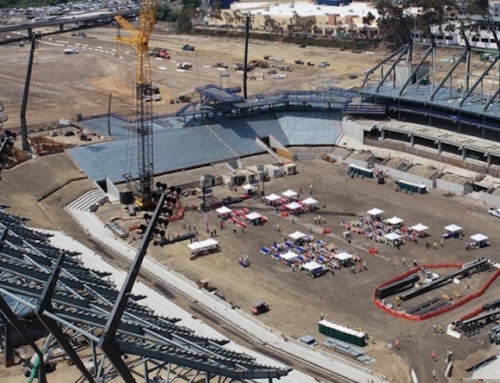

The Phoenix Raceway underwent a $178 million remodel to add a Grandstand structure radiused around the track for spectators to sit and eat while providing views of the track. It also included an expanded and relocated concourse with escalator access, entertainment areas and an underground tunnel system providing access to the infield. All 37 acres of the infield were also redesigned to include garages, fan-experience zones, paths for service vehicles and a new leaderboard.

Project Details

Project Owner:

Contractor:

Structural Engineer:

Architect:

Steel Tonnage:

850 tons

Location:

Avondale, AZ

Schuff Services: preconstruction, structural engineering, BIM services, project management, steel detailing, steel fabrication, steel erection

Schuff Steel’s role was to design assist with the architect and project engineer, fabricate 50% of the structural steel needed, and erect the entire Grandstand while tying back into the existing structure.

Collaboration and thorough planning prior to fabrication was a key component of this project. The build included thousands of bolt holes that had to line up with the mounting posts of the guardrail supplied and installed by others. Our team invested significant effort doing overlays of the other team’s project model and our own to ensure every connection bolt hole was lined up accurately while maintaining project efficiency and timeline.

The attention to detail earlier on in the project proved beneficial during project erection. Schuff Steel’s fabricated steel seamlessly bolted up and helped to reduce labor hours in the field. The project was completed in April 2018.

Let’s talk about

your next project

Phoenix Raceway

Project Details

Project Owner:

Contractor:

EOR:

Architect:

Steel Tonnage:

850 tons

Location:

Avondale, AZ

Schuff Services: preconstruction, structural engineering, BIM services, project management, steel detailing, steel fabrication, steel erection

The Phoenix Raceway underwent a $178 million remodel to add a Grandstand structure radiused around the track for spectators to sit and eat while providing views of the track. It also included an expanded and relocated concourse with escalator access, entertainment areas and an underground tunnel system providing access to the infield. All 37 acres of the infield were also redesigned to include garages, fan-experience zones, paths for service vehicles and a new leaderboard.

Schuff Steel’s role was to design assist with the architect and project engineer, fabricate 50% of the structural steel needed, and erect the entire Grandstand while tying back into the existing structure.

Collaboration and thorough planning prior to fabrication was a key component of this project. The build included thousands of bolt holes that had to line up with the mounting posts of the guardrail supplied and installed by others. Our team invested significant effort doing overlays of the other team’s project model and our own to ensure every connection bolt hole was lined up accurately while maintaining project efficiency and timeline.

The attention to detail earlier on in the project proved beneficial during project erection. Schuff Steel’s fabricated steel seamlessly bolted up and helped to reduce labor hours in the field. The project was completed in April 2018.